The Science Behind Gellner Industrial

There is a wealth of complex knowledge and information behind every water-based acrylic polymer Gellner Industrial creates. And while it’s not necessary to fully understand all of the science in order to be a consumer or enthusiast of Gellner Industrial products, it does help to realize just how high the quality of production is when you’re working with Gellner Industrial.

Gellner Industrial creates water-based acrylic polymers for a variety of purposes, including: vinyl applications and printing processes. A polymer is a substance that has a molecular structure consisting principally or completely of a large number of similar units bonded together. Polymers entail many synthetic organic materials used as plastics and resins. Synthetic polymers are produced by chemical reactions, named “polymerizations.”

Polymers can be characterized by two method of polymerization- addition and condensation.

Most addition polymers are produced via an organometallic compound, known as a Ziegler-Natta catalyst. The Ziegler-Natta catalyst was first developed by Karl Ziegler and Giulio Natta. This discovery led to the two chemists being awarded the Nobel Prize in 1963 for their monumental work.

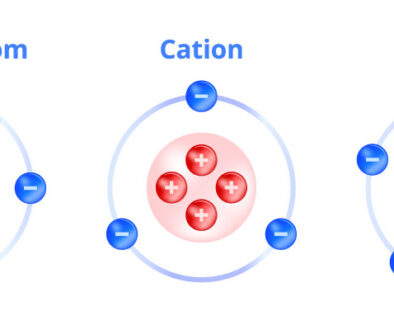

Other addition polymers are produced by creating free radicals (atoms or groups of atoms with an odd/unpaired number of electrons using a compound), that serve as an initiator, to catalyze the reaction.

Many condensation polymerization reactions, in which one or two monomers are the starting materials, also need catalysts and involve many of the same processes as those used in addition polymerization.

Monomers involved in condensation polymerization have functional groups (to learn more about functional groups, check out Gellner Industrial’s blog on polymer products). These functional groups combine to form amide (carboxylic acids in which the hydroxyl group has been replaced by an amine or ammonia) and ester (a compound in which at least one –OH hydroxyl group is replaced by an –O–alkyl group) linkages. When this occurs, a water molecule is removed. Since water is removed, these reactions are referred to as condensation reactions (water condenses out.). When a condensation reaction involves polymerization, it is called condensation polymerization.

An easier way to understand the complex process of polymerization behind the high-quality acrylic polymers manufactured by Gellner Industrial is by comprehending that assorted combinations of heat, pressure and catalysis alter the chemical bonds that hold monomers together, causing them to bond with one another. Most often, they bond in a linear fashion, creating chains of monomers called polymers. Some polymerizations join entire monomers together, whereas others join only portions of monomers and create surplus materials, or by-products. Co-polymers can be formed using two or more different monomers. Two or more polymers can be combined to produce an alloy (a mixture of metals or a mixture of a metal and another element) that displays characteristics of each component.

In summation, polymerization is a process of inciting reactions to bond monomer molecules together to form polymer chains or three-dimensional networks. This process is used by Gellner Industrial to create water-based acrylic polymers for a consistently pleased client base.