Understanding Cationic and Anionic Polymers: Properties, Applications, and Interactions

If you were to browse through Gellner’s website, you’ll likely notice that on many of our product pages, we have separated out our emulsion polymer products by whether or not they are cationic, anionic, or nonionic, with cationic and anionic being the most common categories. Emulsion polymers have a wide range of applications, from water treatment to personal care, and pharmaceuticals to our specialty, coatings and inks.

Cationic and Anionic Polymers–Properties

Cationic

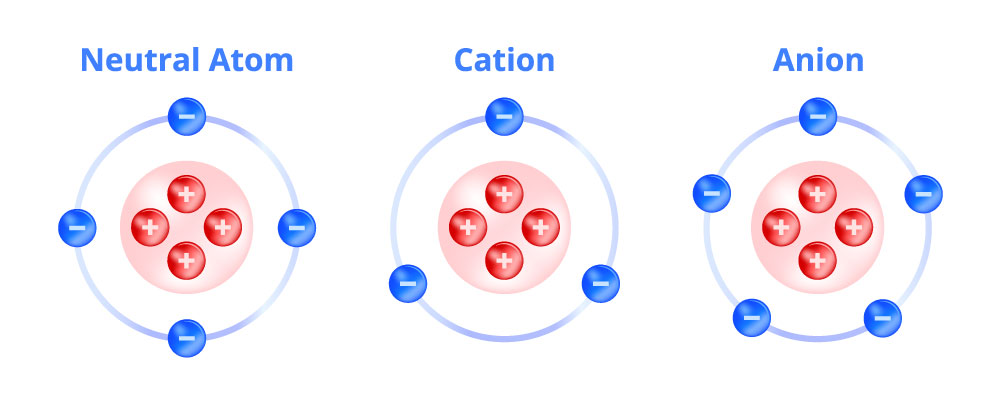

Cationic emulsion polymers are created through cationic polymerization, where a positively charged cation transfers its charge to a monomer, causing a chain reaction between multiple monomers until the polymer is created.

There are only a few polymers that can successfully execute cationic polymerization, so these types of emulsion polymers are not as common. However, because they retain a positive charge, they actually can adhere to a wide range of surfaces that anionic polymers cannot, as most substrates tend to be negatively charged. They also tend to have much more resistance to various environmental conditions due to their cationic nature that anionic polymers cannot endure as well.

Anionic

Anionic emulsion polymers are created through a similar growth chain reaction, but with a negatively charged ion or anion. This anion reacts with a neutral monomer, causing polymerization to occur, and creating the polymer. Anionic polymers are much more common across industries as there are more monomers that can execute anionic polymerization. However, they are also suited to different applications as a result.

Anionic polymers are also very versatile and found in a variety of industries, but are less likely to be used in outdoor applications. However, they tend to exhibit excellent water resistance compared to cationic polymers. In our field, we find that our anionic polymers perform especially well in high pigment inks and various types of printing, due to having excellent adherence to the common substrates used in these industries.

Applications of Cationic and Anionic Polymers

Cationic

Gellner’s cationic acrylic emulsion polymers are used in a wide range of printing inks in order to improve flow, gloss, and solubility. They are especially useful because they provide superior adhesion to nearly any surface, from fabric to wallpaper to various types of packaging plastic. Our cationic polymers are also excellent for paint primers and coatings, especially primers used in outdoor applications, nonporous substrates, or damp environments. Ottopol KO, one of our newer products, can even block stains from tanin oils as well as mold and bacteria on damp basement walls.

Anionic

Gellner’s anionic polymers are excellent agents for acting as binders for house paints and metallic pigments. Our anionic products also serve as excellent additives for flexographic and gravure printing inks, corrosion and water-resistant paints and coatings, cement sealers, and contact adhesives, as well as several other industrial coatings. While many anionic polymers may show lesser resistance to UV rays and wear, Gellner has developed several anionic emulsion polymers for use in wood finishes and sealants that exhibit excellent UV, chemical, and abrasion resistance.

About Gellner Industrial, LLC

Gellner Industrial is a leading manufacturer of high performance water-based acrylic polymers, both cationic, anionic, and nonionic. We have decades of experience in the inks and coatings industry, as well as many different products that you can browse on our website. Contact us with any questions that you may have.