Resins for Electronics

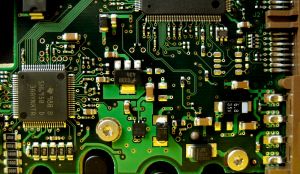

Epoxy resins and polyurethane resins based products protect electronic components from moisture, vibration, shock, overheating, strain, and contamination. A few electronics that resins are used in the production of are circuit boards, strain-sensitive components, coils, and transformers.

For example resins are used in various types of circuit board production:

FR-2 Paper/Phenolic

– A composite material is made of paper that is integrated with a phenol formaldehyde resin.

FR-4 Epoxy

– These circuit boards are made of woven fiber glass cloth with an epoxy resin binder that is flame resistant. The resin used in the manufacturing of this type of circuit board gives the board its electrical insulating property in dry and also humid conditions.

FR-4 High and ultra-high performance

– Circuit boards are used in ultra-high end applications which are based on polytetrafluoroethylene and other varieties of available resin systems

In 2006, there was a ban placed on the use of lead in all electronics. New alloys were used to connect chips and sockets to conductive layers. These new alloys had higher functioning temperatures which required a resin used in the production of circuit boards to contain the necessary properties to handle higher soldering temperatures.

We have the technical expertise to develop resins for the electronics industry because Gellner Industrial, LLC has over a quarter century of experience, product knowledge, and innovative manufacturing expertise to provide our customers with the highest performing resins.