Alkali and Chemical Resistance

Acrylic Polymers for Chemical Resistance

Gellner’s acrylic polymers for corrosion and alkali resistance

When it comes to coatings for outdoor, industrial, or similar applications, an important characteristic that these coatings often require is chemical resistance. This term can be used to cover a wide range of resistances. In this article, we’ll cover two of the more common types of chemical resistance that coatings and varnishes often require–corrosion resistance and alkali resistance.

Corrosion Resistance

You’ve probably seen the effects of corrosion, and have at least a basic understanding of what it is. In order to understand how our polymers work, it’s important to understand what corrosion is.

Corrosion is the loss of metal due to a chemical reaction with liquids or gasses in the environment. There are many different variants of corrosion, based on where on the metal it occurs, as well as the type of reaction or the metal being affected. Once corrosion of a metal begins, it spreads quickly across the surface, and into the interior of the metal part.

Some metals and metal alloys are corrosion resistant, able to form a protective layer on the surface that protects the inner metal from this reaction. However, any alloy can eventually corrode under the right circumstances, which is where corrosion resistant coatings come into play.

Gellner’s polymers for corrosion resistant coatings

Another way to protect metal products from corrosion is to cover it with a coating, such as a corrosion-resistant primer or paint. One of Gellner’s newest polymers, Ottopol SF-49, is a water-based acrylic resin that can be formulated into a resistant primer, or even a semi-gloss paint. The resulting coating works similarly to the protective layer that naturally forms on metal alloys, reacting with the environment to form a barrier over the metal. The dry film of this polymer also is very water resistant, and won’t blush even after extensive exposure to damp, or waterlogged conditions.

| Name | Solids | pH | Viscosity | Tg | Attributes | Data Sheets |

|---|---|---|---|---|---|---|

| SF-49 | 48 - 50% | 7.5 - 8.0 | 500 cps max | 3 | The dry film has outstanding water resistance and will not blush even after prolonged exposure to water. This polymer can be formulated into a corrosion resistant primer or semi-gloss paint. |

Alkali Resistance

The word ‘alkali’ is used to refer to chemicals that dissolve in water and cause a liquid to become less acidic. They are very common in everyday life–alkalis tend to be found in household cleaners and soaps, as well as similar applications.

Alkali resistance, as you probably guessed, is the ability of a coating or surface to resist deterioration that occurs when it reacts with alkaline chemicals. This is an especially important property for furniture coatings to have, as well as on household paper towels.

Gellner’s polymers for alkali resistant coatings

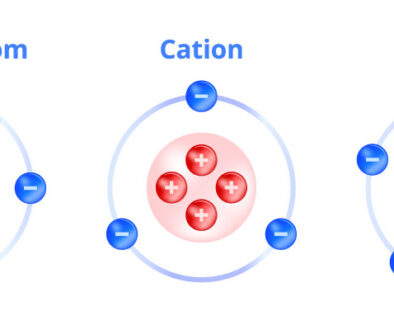

One of our newest products, Ottopol AR-150, has excellent alkali resistance, without the need for extra additives. This acrylic polymer can be formulated into inks and overlay varnishes for products like soap boxes or paper towels, without being affected by the alkalis in the cleaners or soaps used with them. We also have several cationic acrylic polymers, which are all alkali resistant due to their cationic nature.

| Name | Solids | pH | Viscosity | Tg | Attributes | Data Sheets |

|---|---|---|---|---|---|---|

| AR-150 | 39.0 - 41.0% | 8.0 - 9.0 | 200 - 800 cps | 40 | The dry resin is impermeable to alkali without the use of crosslinking agents. Inks and overlay varnishes for soap boxes and household paper towels will not be affected by the high pH of the detergent cleaner used with the paper towels. | |

| SF-45 | 44 - 46% | 7.5 - 8.5 | 100 cps max | 45 | Unique acrylic polymer that results in a high density cross linked polymer upon drying at room temperature. Many Coatings can be derived from this polymer where solvent resistance is required. | TDS | SDS |

| K-672 | 39.0 - 41% | 5.0 - 6.0 | 500 - 1500 cps | 10 | Experimental Ottopol K-672 is a Hydroxyl Functional Cationic Acrylic Emulsion Polymer. | |

| K-12T | 42 - 44% | 4.5 - 5.5 | 200 - 800 cps | 0 | Cationic acrylic emulsion for rust converting primer. Converts rust to black iron oxide. | TDS | SDS |

| K-23 | 41 - 43% | 5.0 - 6.0 | 200 - 500 cps | 26 | Emulsion polymer for alkali resistance and adhesion to non-porous substrates. | TDS | SDS |

| K-65 | 35 - 37% | 5.0 - 6.0 | 200 - 800 cps | 81 | Hard emulsion polymer for alkali resistance. | TDS | SDS |

| K-66 | 39 - 41% | 5.0 - 6.0 | 200 - 500 cps | 87 | Hard emulsion polymer for alkali resistance. | TDS | SDS |

| KO | 42 - 44% | 4.5 - 5.5 | 200 - 800 cps | 0 | Styrene Acrylic Co-Polymer for the latest in stain blocking technology. | TDS | SDS |

| K-362 | 29 - 31% | 5.0 - 6.0 | 200 - 400 cps | 43 | Solution polymer for alkali resistance and adhesion to non-porous substrates. | TDS | SDS |

| K-633 | 28 - 30% | 5.0 - 6.0 | 200 - 400 cps | 44 | Solution polymer for alkali resistance and adhesion to non-porous substrates, improved solubility. | TDS | SDS |

| KX-99 | 29 - 31% | 5.0 - 6.0 | 300 - 800 cps | 32 | Hydroxyl Functional Cationic Acrylic Solution, crosslinks at ambient or elevated temperature for solvent resistant coating. | TDS | SDS |

Looking for a supplier of acrylic resins with chemical resistance?

Gellner Industrial is the premier manufacturer of water-based acrylic polymers. If you’re in need of resins that offer chemical resistance to coatings and inks, we have many products for you to choose from. Check out our website for more information on what we do!