What is Gravure Printing?

What is gravure printing? To understand rotogravure printing, a brief primer of intaglio is required. Intaglio is the process used in printing and printmaking in which an image is incised into a surface and where the incised line – or sunken area – holds the ink. There are many applications for intaglio, such as the decoration of armor, musical instruments, and religious objects, as well as mass-printed stock certificates, maps, magazines, newspapers, fabrics, sheet music, wallpapers, banknotes, passports, and high-value postage stamps.

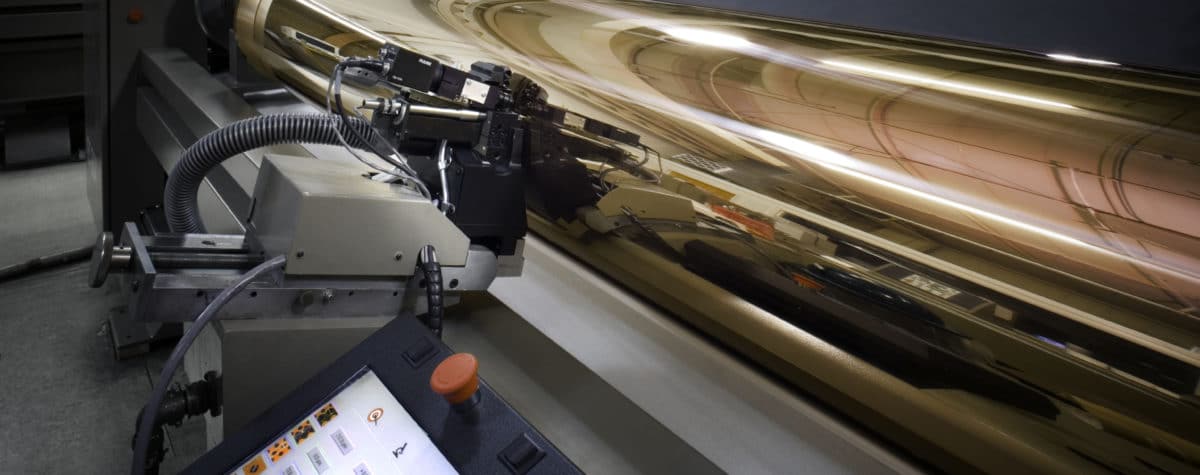

Rotogravure – gravure for short – is a type of intaglio printing process which utilizes an engraved cylinder fixed to a rotary printing press. Gravure printing is still widely used for the commercial production of post cards, magazines, newspapers, and corrugated cardboard (and other packaging materials). Rotogravure is utilized when the job calls for fine, detailed images in a high-speed, high-quality, and long-run printing process.

How Does Gravure Printing Work?

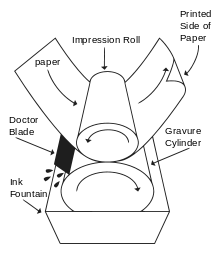

First, the image is acid-etched onto the surface of a metal cylinder. These etches are called “cells” and are recessed into the metals in varying degrees of depth; there are minute differences in the depth of the etchings which provide tonal gradations in the printed image; for example, an etching with a greater depth will have less ink, creating a lighter image than a cell with a smaller depth . After the image is etched, the cells are filled with printing ink while the rest of the cylinder is wiped clean. Part of the cylinder is immersed in the ink fountain while paper (or another printing medium) is pressed against the cylinder. The image will be transferred directly to the paper.

The process of replicating photos in gravure printing is called photogravure, where a copper plate is grained and then coated with a light-sensitive substance which has been exposed to a film positive.

Reasons to Use Gravure Printing

- Gravure printing is incredibly consistent and can provide uniform color and copies throughout a press run, even if the run consists of several million copies.

- Gravure printing does not have a lot of variables to control. As such, a simpler process ensures a consistent print quality throughout the run and less error in printing.

- Gravure printing is a direct printing process. Since the image that is etched on the cylinder is printed directly to the printing medium, superior ink laydown and image rendering is a given.

- No plate seam is shown with gravure printing, as the printing data is continuously wrapped around the cylinder.

- Gravure printing production speed is high: 3000-3300 feet per minute.

- Cylinders are extremely durable and reusable and can print runs of 2-3 million from one set of cylinders.

Gravure Inks

Gravure printing inks, that were originally composed of mainly solvent-based ingredients, are gradually being replaced by alternative solutions. Water-based inks are now the most popular solution for gravure printing due to their safety (solvent-based inks are toxic and flammable) and environmentally-friendly characteristics.

Resins for Gravure Printing Inks

Gellner Industrial is an industry leader in the manufacture of water-based acrylic polymers and resins for Gravure printing inks. Gravure printing inks are generally used for more expensive printing applications such as catalogs, cartons, gift wrap, and newspapers, as well as vinyl floors and wallpapers. Gellner Industrial’s high-quality polymers can be used to produce gravure printing inks that will outperform conventional resins in terms of solubility, gloss, hold-out, and flow. Gravure printing inks produced with our resins will not dry in the screen when the press encounters down time and will outperform any conventional resin. For more information, click here for our contact page or give us a call at (570) 668-8800 for a free quote.